بيع ساخن

التطبيق

Phone:+86-15215969856 E-Mail: 396838165@qq.com

Walk into any fancy interior design office these days, and you will spot a big change in what clients want. The time of plain, factory-made light brown curtains and basic bedding is going away quickly. In 2026, the popular style is very personalized options. People who own homes and those who run hotels desire tall drapes with strong, exact designs and full carpets that fit their small pillows just right. For companies that offer printing services, this need is a great chance to earn better profits. Yet, it also brings a tough practical problem. Printing a shirt is easy; but creating a smooth 3-meter wide curtain without any color change is a whole different challenge. Many places attempt to use their small clothing printers for this hard work, only to struggle with ruined cloth and late deliveries. To really grab this market, you have to rethink how you make things.

The Shift to Wide-Width Production in Home Textiles

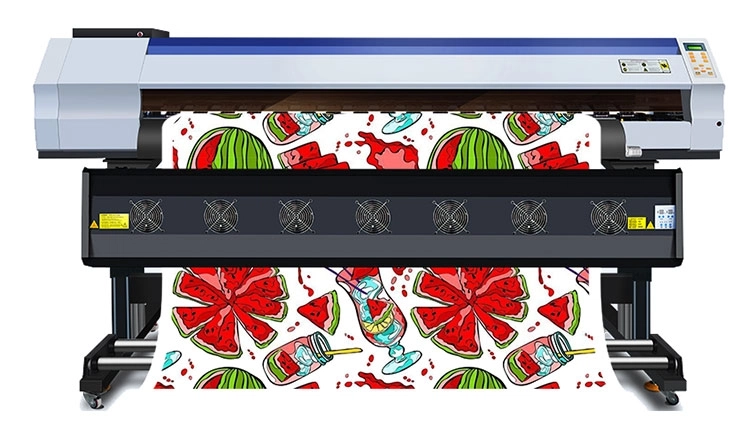

The most obvious barrier to entering the home furnishing market is physical size. Standard 1.6-meter printers, the workhorses of the fashion industry, simply cannot cut it for interior decor. If a client wants a seamless look for a large bay window, stitching two pieces of fabric together is often a deal-breaker. It ruins the aesthetic flow and lowers the product’s value. Consequently, upgrading to a large-format sublimation printer—typically 3.2 meters wide—is the entry fee for this sector. But buying a bigger machine is only the first step. You need to understand how the physics of printing changes when you double the width of your media.

Conquering the Seamless Curtain Market

When you move into wide-format production, you are selling luxury. A large-format sublimation printer allows you to produce massive panels of fabric in a single pass. This is critical for items like curtains, where pattern alignment is everything. Matching a complex geometric pattern across two separate pieces of fabric is a nightmare for your sewing team and often results in rejected orders. By printing the full width at once, you eliminate sewing labor and misalignment risks.

However, this demands precision. A 3.2-meter span means the print carriage has a long way to travel. If the machine lacks a robust frame, carriage movement causes vibrations, leading to “banding” or soft edges. High-quality machines, like the industrial models from تشانغفا الرقمية, use heavy steel structures to absorb this energy, ensuring pixel placement is sharp across the entire width.

Handling Heavy Media Tension

Another factor that catches newcomers off guard is the weight of the material. A 3-meter wide roll of wide-width sublimation paper is significantly heavier than a standard fashion roll. If your digital printer lacks a sophisticated feeding system, the paper will drag or skew. This leads to “cockling,” where the paper ripples under the printhead.

When paper bends, the print head could hit the top, which might break costly parts. Expert wide-format machines use strong tension rods and air-shaft setups to hold the center tight. They add steady pull to keep the paper flat, even when full of ink. This exact control lets you print 100 meters of cloth patterns without watching, and you avoid stops.

Stability vs. Speed: What Actually Makes Money?

There is a trap many business owners fall into: becoming obsessed with top speed. Manufacturers love to advertise a high-speed sublimation printer that can do 300 square meters per hour. While speed is great, stability is what pays the bills in home textiles. A machine that sprints but trips every few kilometers is useless for long runs. When printing huge rolls for a hotel contract, reliability is the only metric that matters. You need a machine that produces the same quality at minute 600 as it did at minute one.

The Hidden Cost of Downtime

Let’s talk about numbers. Suppose a super-fast printer requires operator intervention every 40 minutes due to nozzle clogging or paper drift. Every stop costs you money—time to fix the issue, wasted material, and lost production rhythm.

A stable sublimation printer might run slightly slower on paper, but if it runs 24/7 without stopping, its daily output will crush a faster, temperamental machine. This stability comes from quality components, like Japanese guide rails, that don’t degrade under load. It also relies on negative pressure systems to keep ink supply consistent. In the home textile game, where an order might be 5,000 meters of matching fabric, a machine that stops halfway can ruin the color consistency of the entire batch. Reliability protects your reputation.

Achieving Color Consistency on Long Runs

Clients for home decor are known to be fussy. If a buyer gets curtains now and asks for a matching pillow later on, the shades must match exactly. Or, if you are printing a 50-meter roll for a wall cover, the blue at the beginning cannot turn into purple by the finish. This “color shift” occurs when power changes or the ink setup slows.

To manage this, better dye sublimation home textiles tools use ink systems that circle back. These keep the ink stirring even when not in use, stopping bits from settling. Also, heat control makes sure the boards do not get too warm. Special makers like تشانغفا الرقمية put a lot of effort into these steady features, so your “Royal Blue” remains true for the full kilometer of printing.

The Strategic Advantage of Jumbo Roll Consumables

Hardware is only half the battle. To truly scale and reduce costs, you must look at what you feed the machine. In the past, the industry standard was small, 100-meter rolls of transfer paper. While fine for fashion, they are a bottleneck for industrial home furnishing. Changing a roll requires stopping the machine, loading the new roll, threading, and testing. This process wastes time your machine should spend making money. The solution lies in shifting to jumbo rolls supplied by a capable sublimation paper manufacturer.

Reducing Changeover Frequency

Picture a big order for bed covers. If you use regular 100-meter rolls and your printer goes at 100 square meters per hour, you stop the machine about every hour. That means 8 to 10 halts per work time, where your worker has to care for the machine.

By changing to wide-width sublimation paper on jumbo rolls—usually 1,000 meters or more—you alter the setup. You set up the machine on Monday, and it keeps going until Tuesday without a paper switch. This lets one worker handle several printers at once. The savings on work are huge, turning your process from a jerky stop-and-start into a steady flow of making.

Minimizing Material Waste

There is also a direct material cost benefit. Every time you finish a roll, about 2 to 3 meters are unusable because they are taped to the core. Additionally, loading a new roll wastes another meter on threading and color bars.

If you print 1,000 meters using ten small rolls, you waste 30 to 50 meters of paper on setups. Using a single 1,000-meter jumbo roll, you waste that material only once. Over a year, a busy factory saves thousands of dollars just by reducing this scrap. Sourcing from a specialized sublimation paper manufacturer allows you to order these specific lengths, ensuring you squeeze every bit of value out of your inventory.

Meeting the Green Standard with Modern Inks

By 2026, sustainability will be a strict requirement for doing business with major retailers. Europe and North America have tightened regulations regarding chemical safety in textiles, especially for products contacting skin like bedsheets. Old solvent-heavy processes are dying out. Today, to land contracts with big home furnishing brands, your production line needs to be clean. This is where the chemistry of your consumables becomes just as important as the mechanics of your printer.

I.Safety for Indoor Use: Traditional dyeing often uses harsh chemicals. Sublimation is inherently cleaner, but the ink matters. Using high-quality, Eco-friendly sublimation ink ensures the final product is free from volatile organic compounds (VOCs) and heavy metals. This is non-negotiable for nurseries and bedrooms.

II.Water-Based Efficiency:Modern water-based sublimation inks dry fast and release color efficiently. Because they are highly concentrated, you use less ink to get vibrant colors. This prevents the paper from getting too wet (reducing cockling risks) and improves drying times. You use less material for better results, lowering both your environmental footprint and cost per square meter.

استنتاج

The home furnishing market in 2026 offers incredible opportunities for those ready to adapt. Scaling up isn’t just about buying a wider printer; it’s about building a stable ecosystem. By choosing a robust, large format sublimation printer that prioritizes stability and feeding it with cost-effective jumbo rolls of wide-width sublimation paper, you create a production line that generates profit reliably.

Don’t let outdated equipment hold you back. The shift to wide-format is happening now. If you are ready to explore how industrial-grade stability and smart consumable choices can transform your profitability, check out the solutions offered by تشانغفا الرقمية. Contact us now at 396838165@qq.com; our expertise in both hardware and media will help you build the high-quality production floor your customers demand.