HOT SALE

APPLICATION

Phone:+86-15215969856 E-Mail: 396838165@qq.com

Have you ever wondered how those vibrant, long-lasting, colorfast sportswear, throw pillows, or intricately patterned polyester jackets are brought to life? The answer lies in a magical printing technology: thermal sublimation printing. Today, we’ll uncover its secrets and introduce you to a powerful partner that can help you achieve twice the result with half the effort: 50gsm sublimation transfer paper!

How Does Sublimation Transfer Paper Work?

The working principle of sublimation printer paper differs from traditional printing, which involves “painting” onto fabric. Conventional printing (such as screen printing and direct inkjet printing) is like “pasting” a layer of pigment onto the fabric, much like painting a wall. This feels heavy, prone to cracking and fading, and is stiff and airtight. Dye sublimation transfer printing, on the other hand, is completely different. This technology vaporizes the ink, allowing it to penetrate the polyester fibers and solidify upon cooling, thereby becoming an integral part of the fiber. This allows the fabric and ink to become one.

The basic principle of thermal sublimation printing is to vaporize ink at high temperatures, allowing it to penetrate the fabric. First, a special sublimation ink is used to print a mirror image of the design onto transfer paper. The transfer paper is then placed over polyester fabric or a high-polyester blend and fed into a high-temperature heat press. Finally, under the influence of high temperatures, the ink instantly sublimates into a gas, penetrating directly into the polyester fibers and recondensing into a solid, ultimately making the design part of the fabric.

The fabric produced by heat sublimation transfer printing surpasses conventional printing techniques. First, you’ll find the fabric feels smooth to the touch, with the printed area 100% consistent with the original feel, free of adhesive and stiffness. Furthermore, the dye is highly integrated with the fiber, resulting in a long-lasting, fade-resistant color that remains vibrant after 50+ machine washes. The dye doesn’t clog the fabric’s pores, ensuring breathability and quick-drying properties. Finally, custom patterns can be reproduced in high definition, reproducing photo-quality gradients without blurring or smudging details.

Just like injecting colorful soul into fabrics, thermal sublimation printing is not just “putting on outer clothes” for clothes, but making the colors become part of the fabric!

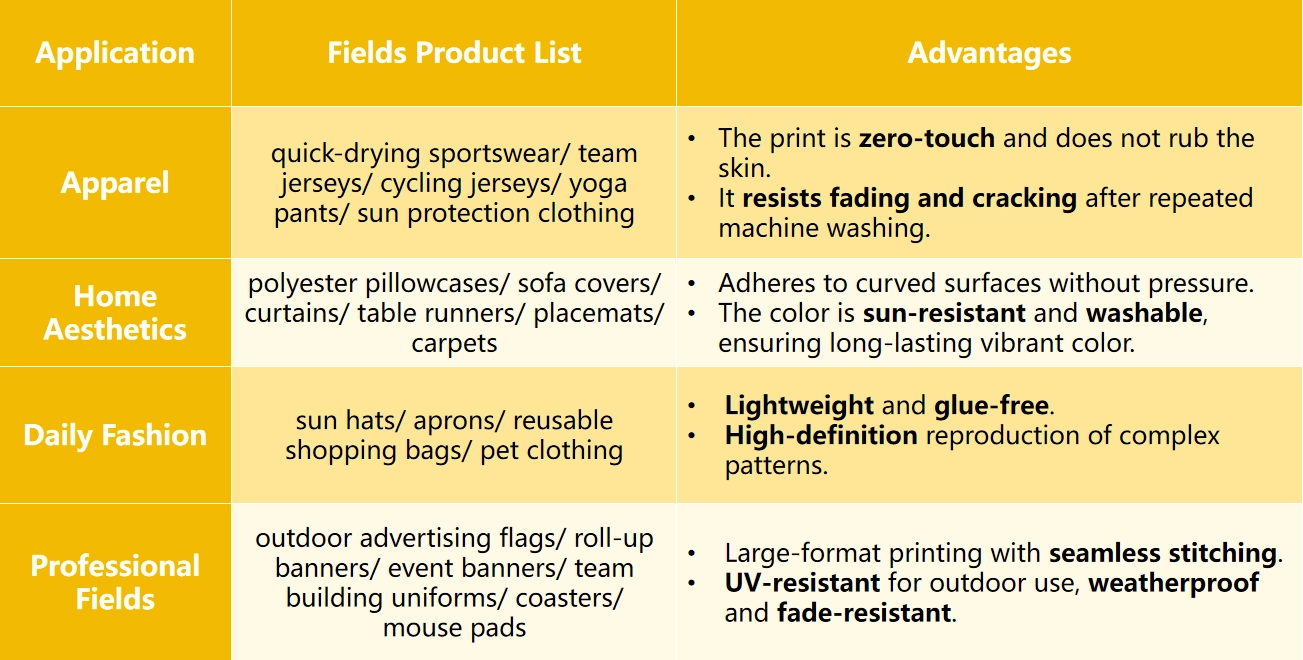

What Items Are the Best Candidates for Heat Sublimation Transfer?

Heat sublimation transfer technology is particularly fond of polyester! When it comes to polyester or high-polyester blended fabrics, this technology will burst out with amazing potential! Fabrics with a polyester content of more than 65% are its best partners.

However, dye sublimation thermal transfer isn’t all-purpose. Use caution with the following materials:

Pure cotton/ Linen/ Silk/ Wool: Natural fibers lack the chemical “door-opening” mechanism of high temperatures, so the dye can’t penetrate. Rubbed away after transfer!

Dark Pure Polyester: The ink is a transparent gas and won’t cover dark base colors (only suitable for white or light-colored fabrics).

Hard Metal/ Plastic: Special coating is required, although coated products are partially suitable.

Why Do Designers and Manufacturers Love It?

For designers, the dye sublimation thermal transfer process perfectly reproduces the colors of designs. Conventional printing is limited by dot overlays, making it difficult to reproduce vibrant gradients. However, dye-sublimation supports 26 million colors with smooth transitions (color difference <3%). Furthermore, dye-sublimation transfer paper offers high-definition output, allowing for the perfect reproduction of ultra-fine designs like hair and feathers, eliminating the blurring issues associated with traditional printing.

For manufacturers, this technology is a powerful tool for reducing costs and improving efficiency. First, heat sublimation transfer technology allows for on-demand production, with a minimum print run of one piece, and production begins upon receipt of the order. This keeps costs under control and eliminates the inventory risk associated with a “minimum order of 1,000 pieces,” making it particularly suitable for manufacturers of small, custom orders. Second, heat transfer technology offers advantages in cost savings of over 50% compared to traditional printing processes, thanks to its computer-based operation, the limited materials required, transfer paper and ink, and zero wastewater. Finally, the product offers a premium price point. Selling features such as “nude prints” and “colorfast after 100 washes” can increase product pricing by 30%.

Finally, regarding environmental protection and customization, its waterless process, combined with biodegradable transfer paper, complies with global environmental regulations, helping you easily secure orders from Europe and the United States. This process allows for seamless transitions from single-piece customization to batch orders of 10,000 pieces, allowing small factories to handle large orders and large ones to handle smaller ones, ensuring a balanced and efficient use of resources.

Advantages of Changfa Digital’s 50gsm Fast-Drying Sublimation Paper

In the entire thermal sublimation printing process, sublimation printer paper is the key medium to carry ink and ensure perfect transfer. Lightweight heat sublimation transfer paper is the key assist in this process. Take Changfa Digital’s 50gsm instant dry sublimation paper as an example. Its light weight is redefining industry standards:

Lightweight & Low Cost: “50gsm” refers to the weight per square meter. Compared to thicker 70gsm or 100gsm paper, 50gsm sublimation paper is significantly lighter and thinner. This not only means lower paper costs, but more importantly, thin paper absorbs less ink. This allows for more efficient ink transfer to the fabric, saving you valuable ink costs!

Smooth Printing: The paper’s thinness gives the transfer paper exceptional flexibility. It’s less likely to curl, wrinkle, or jam when feeding through the printer and laminating to curved surfaces in the heat press, ensuring smoother operation.

High Transfer Rate: Its special coating, designed specifically for dye sublimation ink, locks in the ink. It allows for precise positioning during printing and instantly and completely releases all ink vapor at high temperatures, leaving no ink residue. This ensures vibrant colors and an extremely high transfer rate. The transfer rate of Changfa Digital’s 50gsm sublimation paper can reach over 98%.

Soft Touch: Because the paper is thin and the ink release is thorough, the transferred dye is fully integrated into the fabric, ensuring a soft feel to the printed area. This is the key to comfort in sportswear, base layers, and pillows!

Conclusion

From athletes’ sportswear to pillows that hug our skin daily, from advertising flags exposed to the sun outdoors to trendy backpacks that carry our personality, heat sublimation transfer technology has become an invisible part of our lives and is everywhere. Among the wide range of sublimation papers developed by Changfa Digital, covering 29, 35, 40, 50, 60, 70, 90 and 100gsm, products below 50gsm are categorized as lightweight papers, which are especially popular in certain textile applications. Our 50gsm instant dry sublimation paper not only redefines the ceiling of printing quality and completely liberates the boundaries of creativity, but also represents a future trend under strict environmental standards.

Changfa Digital’s 50gsm Fast Dry Sublimation Paper is made from high-quality imported raw materials, from base paper to coating. Our products have high slitting precision, and the printer paper feed has almost zero deviation. We strictly control the quality of the entire process from production to transportation to ensure stable delivery. At the upcoming Digital Textile Printing Industry Expo in Lahore, Pakistan (August 30–31, 2025), Changfa Digital will primarily showcase its lightweight sublimation papers, highlighting innovations in low-grammage products. This will be a valuable opportunity to exchange insights with global industry partners.

Changfa Digital doesn’t trade low prices for market share. We use the triple advantage of base paper purity, coating technology, and slitting precision to ensure that our customers don’t waste a single drop of ink! If you have any customized requirements, please contact our experts at 396838165@qq.com.