HOT SALE

APPLICATION

Phone:+86-15215969856 E-Mail: 396838165@qq.com

You’ve created a cool design and want to print it on a cotton T-shirt, a ceramic mug, or even a pair of sneakers. You do an online search and are immediately confused by two technical terms: DTF and dye-sublimation. Which should you choose? It’s not just a matter of choosing a printer; it’s about choosing the entire creative process from screen to physical object.

In the quick-changing world of custom printing, knowing these ways can help a lot. DTF, or direct-to-film, has become popular for its easy use on common fabrics. Dye-sublimation, however, does well in giving clear, long-lasting colors on man-made materials. This guide explains it for you in 2025. It looks at how each works with sublimation printers, sublimation ink, and the right software. We will check workflows, tools, and tips to help you pick the best sublimation printer for your setup. By the end, you will see why a good sublimation ink printer with fine sublimation transfer paper can change your projects.

The Core Differences: DTF vs. Sublimation

At their heart, DTF and sublimation take different paths to bond ink to material. Both deliver vibrant results, but the mechanics—and what they demand from your sublimation printer—set them apart. Let’s start with the basics of how ink interacts with fabric in each process.

How They Work: Ink and Fabric Bonding

DTF printing starts with a film sheet. You print your design using special DTF inks, which include a white underbase for dark fabrics. Then, adhesive powder goes over the wet ink. Heat cures the powder into a sticky layer, and a final press transfers the whole thing to the fabric. The bond forms as the ink embeds into the fibers, creating a durable print that flexes with the material.

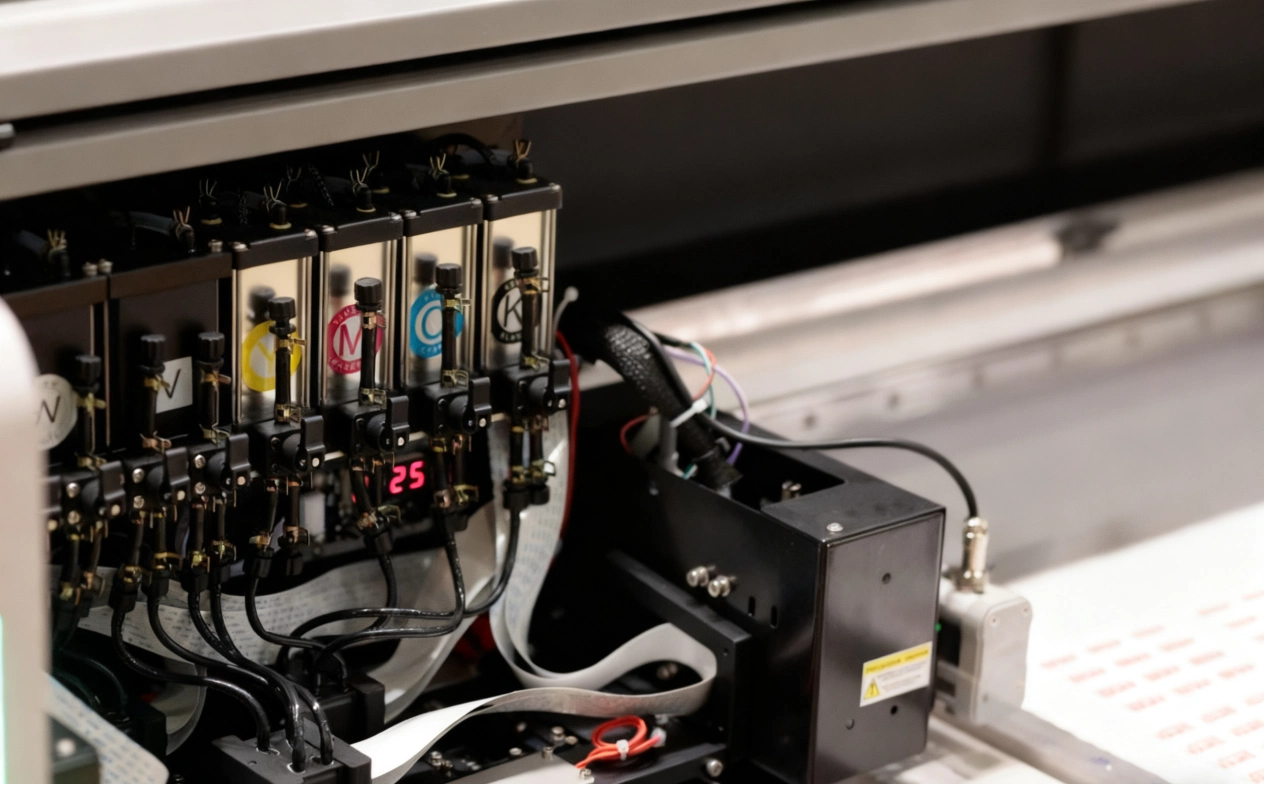

Sublimation follows a heat-driven transformation. Here, sublimation ink in your sublimation ink printer turns to gas under high temperatures. That gas infuses directly into polyester or coated surfaces, becoming part of the fabric itself. No added layers. No texture. Just pure color penetration. This makes dye sublimation paper essential—it’s the carrier that holds the design until the heat press works its magic.

These approaches shape everything from prep time to final durability. DTF’s powder step adds a tactile element, while sublimation’s gas phase ensures seamless integration. But how does this play out in what you can actually print on? The next section dives into material limits, showing why one might suit your stock better than the other.

Material Compatibility: What Can You Print On?

DTF stands out for its broad reach. It adheres well to cotton, blends, leather—even wood or metal with coatings. Dark fabrics? No issue, thanks to that white ink layer. In 2025 tests, DTF prints hold up through 50+ washes on 100% cotton without cracking. It’s the go-to for versatile apparel runs.

Sublimation demands polyester or polymer-coated items. Your sublimation transfer paper works best on 65%+ polyester fabrics, mugs, or mouse pads. Colors pop brighter—up to 95% vibrancy retention after 100 washes on coated surfaces. But try it on untreated cotton? The ink fades fast. That’s where picking the best sublimation printer matters; models tuned for sublimation ink ensure even gas diffusion.

Material choice ties directly to feel and expense. A print on polyester via sublimation feels soft, like the design was woven in. DTF might leave a slight rise, noticeable up close. As we move to costs, keep this in mind—your budget will reflect not just the machine, but the ongoing supplies like sublimation printer paper rolls.

Upfront Investment and Hand Feel

Entry-level DTF kits run $500 to $1,500, including a printer, powder shaker, and heat press. DTF printing requires the continuous consumption of specialized ink, PET film, and hot-melt powder. Statistics show that 1kg of white ink costs approximately $15, and 1kg of hot-melt powder costs approximately $7. Prints have a subtle texture—about 0.1mm thick—from the adhesive layer. It’s stretchy, but that raise can catch on nails after heavy wear.

Sublimation setups start higher, around $1,000 for a basic sublimation ink printer, inks, and press. The hand feel? Invisible. Ink dyes the fibers, leaving a smooth surface that breathes like untreated cloth.

For high-volume shops, DTF’s material freedom justifies the extra $500 upfront. But if polyester rules your line, a sublimation printer saves cash long-term. These contrasts lead naturally to the tools that drive both: software. Without the right programs, even the best sublimation printer sits idle.

The Essential Software: Powering Your Printer

Software bridges your vision to the press. It handles everything from sketching ideas to fine-tuning colors for your sublimation ink printer. In 2025, options blend ease with power, fitting both DTF and sublimation workflows. We’ll cover the building blocks first, then spotlight standouts.

Design Software: From Idea to Digital File

Start with tools that export high-res PNGs or PDFs—must-haves for both methods. Adobe Illustrator handles vectors for scalable logos, perfect for resizing without blur on a sublimation printer. CorelDRAW mirrors this, adding built-in color libraries tuned for sublimation ink profiles.

For quicker sketches, Procreate on iPad shines for hand-drawn art. Export at 300 DPI, and you’re set for dye sublimation paper feeds. These apps work across DTF and sublimation, as the core file prep stays the same. But once files are ready, RIP software steps in to manage the print job itself.

RIP tools act as the conductor. They queue designs, adjust for ink types, and prevent waste—crucial when feeding rolls of sublimation printer paper.

RIP Software: The Brain for Color and Print Control

RIP, or raster image processing, software translates your file into printer commands. For DTF, it layers white ink first, then colors, and nests multiple designs to cut film waste by 20%. Sublimation RIPs focus on color mapping—converting RGB to the gas-friendly profiles of sublimation ink.

Key perks include banding fixes and ink limits to avoid clogs in your sublimation ink printer. Nesting saves $100+ per 100 sqm roll of sublimation transfer paper. Without it, colors shift; with it, you hit 98% match to screen previews.

Top Software Recommendations for 2025

Picking the right combo depends on scale. Here’s a quick rundown:

I. Adobe Creative Cloud(Photoshop+Illustrator): Best for complex DTF layering; integrates sublimation printer software profiles out of the box. Handles 4K exports flawlessly.

II. CorelDRAW Graphics Suite: Strong in nesting for sublimation transfer paper. Built-in RIP lite for small runs—saves $200 on add-ons.

III. Canva Pro: Beginner-friendly templates. Drag-and-drop for quick DTF mocks; exports optimized for dye sublimation paper. Great for teams testing sublimation printer ideas.

IV. Affinity Designer: No subscription. Vector tools rival Adobe; pairs with free GIMP for raster tweaks in sublimation workflows.

These cover 80% of users, per industry surveys. Pair with printer-specific RIPs like AcroRIP, Maintop6.1, and NeoStampa for full control. Looking ahead, software gets smarter. By 2026, expect shifts that cut manual tweaks even further.

Powerful AI Integration for 2026

AI tools are creeping in, automating color tweaks for sublimation ink variations. CorelDRAW’s 2026 update promises auto-nesting that boosts efficiency by 30%, scanning designs to fit sublimation printer paper rolls perfectly. For DTF, AI could predict powder spread, reducing trial runs.

Workflow Breakdown: From File to Product

Workflows turn ideas into inventory. Sublimation flows smoothly on synthetics; DTF adds steps for universality. Both need precision, but one’s quicker for bulk polyester jobs. We’ll detail each, then compare side-by-side. Sublimation’s steps emphasize heat and timing. It’s streamlined, especially with tools like the Sublimation Paper from Changfa Digital.

The Sublimation Printing Workflow

I. Design in software—export mirrored PNG at 300 DPI.

II. Load sublimation transfer paper into your sublimation ink printer. Use CF Sublimation Paper, designed specifically for polyester fabric—it feeds without jams and holds ink evenly for 1900mm-wide runs.

III. Print with sublimation ink. A top model like Changfa’s CF-2000 hits 105 sqm/hour in 2-pass mode.

IV. Weed excess (rarely needed). Align print face-down on fabric.

V. Heat press at 400°F for 60 seconds. Ink gases in.

VI. Peel hot—design’s embedded. Cool and wear.

The DTF Printing Workflow

I. Design with white channel; export to RIP.

II. Print on PET film via DTF inks—white first.

III. Shake on adhesive powder; shake off excess.

IV. Cure in oven at 300°F for 3-5 minutes.

V. Pre-press fabric to flatten.

VI. Press transfer at 320°F for 15 seconds.

VII. Peel warm; post-press 10 seconds more.

Your Decision-Making Guide: How to Choose in 2025

Picking between DTF and a sublimation printer boils down to your goals. Ask pointed questions, weigh scenarios, and lean on proven kits. An integrated system often leads to fewer problems. If you choose the sublimation route, opting for Changfa Digital streamlines it all.

Key Questions to Ask Yourself

What’s your main fabric? Cotton-heavy? DTF. Polyester focus? The sublimation ink printer.

Volume matters: Under 200 units/week? Sublimation’s lower ink use wins. Over? DTF scales.

Skill level: New to this? Sublimation’s fewer steps ease in.

These narrow it fast. For polyester pros, dye sublimation paper setups cut errors by 25%.

Scenario-Based Recommendations

Solo crafter with mugs and tees? Sublimation. Its brights on coated blanks outshine DTF’s texture. Small shop on cotton apparel? DTF. Handles blends without pre-treatment. But for hybrid lines, test both—many run parallel setups. Apparel brand scaling polyester sportswear? Best sublimation printer territory. Pair with sublimation printer software like Maintop for nesting, slashing paper waste.

Conclusion

Sublimation can provide excellent effects with bright colors and a seamless feel on polyester fibers and coated fabrics, while DTF has amazing fabric adaptability. Choosing a trustworthy partner like Changfa Digital provides a solid and worry-free starting point for your creative journey. Our CF-2000 sublimation printer, with its double-head nozzles and 3L ink tanks, tackles wide-format jobs effortlessly. Ready to dive in? Contact Changfa Digital today at 396838165@qq.com to explore the full sublimation transfer paper digital printer lineup. Let’s turn your designs into reality.