ホットセール

アプリケーション

Phone:+86-15215969856 E-Mail: 396838165@qq.com

The first cinnamon-spiced latte of the season, the familiar melodies in shops, and the eager anticipation of gift-giving—the magic of Christmas is in the air. For consumers, it’s a time of joy. However, for manufacturers and print shops, Christmas is both the busiest and the most demanding time of year. Customers want fast turnarounds for family pajamas, custom stockings and small-run décor. That demand puts pressure on production lines, and any slowdown can cost thousands in lost sales. The right materials make a clear difference: high-speed dye sublimation transfer paper and reliable sublimation printing supplies let you convert seasonal interest into steady revenue. This article explains how dye sublimation paper and sublimation transfer papers help printers meet tight deadlines, produce eye-catching Christmas sublimation prints, and keep profit margins healthy during the busiest season.

Christmas Rush Demands Superior Speed & Efficiency

Before we dig into workflows and design, it’s worth noting one simple fact: time is money. During November and December, order volume commonly rises 3–5× for seasonal items in small and medium print shops. Meeting that surge requires materials that run fast, feed smoothly and reduce stoppages. High-speed dye sublimation transfer paper is built for that. It supports quicker job changeovers, stable dot transfer and reduced reprints — all of which keep throughput high without sacrificing product quality.

私はBeat Deadlines with Faster Production Cycles: High-speed dye sublimation transfer paper lets presses run longer at top speeds. Typical dye-sublimation printers in commercial shops operate between 40–100 m² per hour depending on the printer head and ink set. With transfer paper that accepts ink uniformly, you reduce nozzle cleaning cycles and reprints. The result: more finished pieces per shift and fewer urgent night runs.

II.Minimize Downtime and Maximize Output: Downtime often comes from jams, misfeeds and inconsistent transfer. Using consistent-weight sublimation transfer papers lowers these risks. When paper behavior is predictable, operators spend less time adjusting tension and more time producing. For a 10-person shop, that can mean adding an extra 200–500 printed garments during peak weeks.

Capture the Premium Holiday Market with High Quality

Holiday buyers are picky. They will pay extra for vivid, long-lasting prints on high-quality items. That creates an opportunity: shops that combine strong design with stable sublimation print products pull premium prices and repeat business.

High visual quality matters most when shoppers choose gifts. Bright, well-defined Christmas sublimation transfers and consistent color across runs make products pop on shelves and online. Below we look at the production details and brand benefits that come from prioritizing color, texture and material pairing.

私はAttractive Christmas Print Designs: A good design must translate well from screen to fabric. Dye sublimation paper plays a direct role: it holds ink in a way that releases smoothly during heat transfer, preserving gradients, tiny details and text legibility. This makes it easier to reproduce complex designs — snowflakes with crisp edges, metallic-look ornaments, or hand-painted-style illustrations — without extra post-processing.

II.Vibrant Prints that Sell Themselves: Vibrant prints increase perceived value. When a print shop uses high-quality dye sublimation transfer paper together with quality sublimation inks and heat presses, colors stay rich and sharp. That leads to higher average order values and lower return rates.

III.Build a Brand Known for Excellence: Repeatedly delivering reliable Christmas sublimation prints builds trust. Retailers and small brands prefer partners who meet schedules and deliver comparable color across batches. Over three holiday seasons, shops that consistently maintain color profiles and minimize reworks typically see a 20–40% rise in wholesale repeat orders.

Strategic Advantage for Short-Run and Custom Orders

The personalization trend is strongest at the holidays. Shoppers want unique, meaningful gifts — and that means small batches and quick turnarounds. Substantial opportunity exists for printers who can make short-run production profitable.

Small batches require different thinking than mass production. You must keep setup costs low, reduce waste, and run flexible processes. Choosing the right sublimation printing supplies and transfer paper makes it economically viable to create personalized product lines without complex overhead.

Profit from the Personalization Trend

Small-batch customization — family pajama sets, name-tag stockings, limited-run ornaments — can be priced at a premium. Here are practical ways to make those orders profitable:

I.Use mid-weight sublimation transfer papers (35gsm–60gsm) for a balance of speed and handling.

II.Standardize palettes and templates to cut design time; typical template reuse can reduce design time by 40%.

III.Offer bundles: combine a personalized item with a printed card or gift wrap to raise average order value by 15–25%.

Adapt Quickly to Trending Designs

In the age of social media, a Christmas trend can go viral overnight. A quirky design for matching family pajamas, a charming character on a coffee mug, or a witty phrase on a holiday T-shirt can explode in popularity without warning.

When a design goes viral, speed is everything. A shop with ready-to-run dye sublimation paper and pre-tested color profiles can take a trending design from concept to finished product in 24–48 hours. Fast response not only captures immediate sales but also positions the brand as trend-aware — a key differentiator in crowded marketplaces.

Smart Inventory Planning for a Stress-Free Season

Inventory matters more than many shops realize. The right mix of sublimation transfer papers by weight prevents last-minute shortages and keeps storage costs down.

Good inventory planning combines historical sales data with material lead times and weight-specific usage. Below is a practical table and guidance to plan effectively so you never miss an order while avoiding excess stock.

Reduce Waste and Optimize Storage

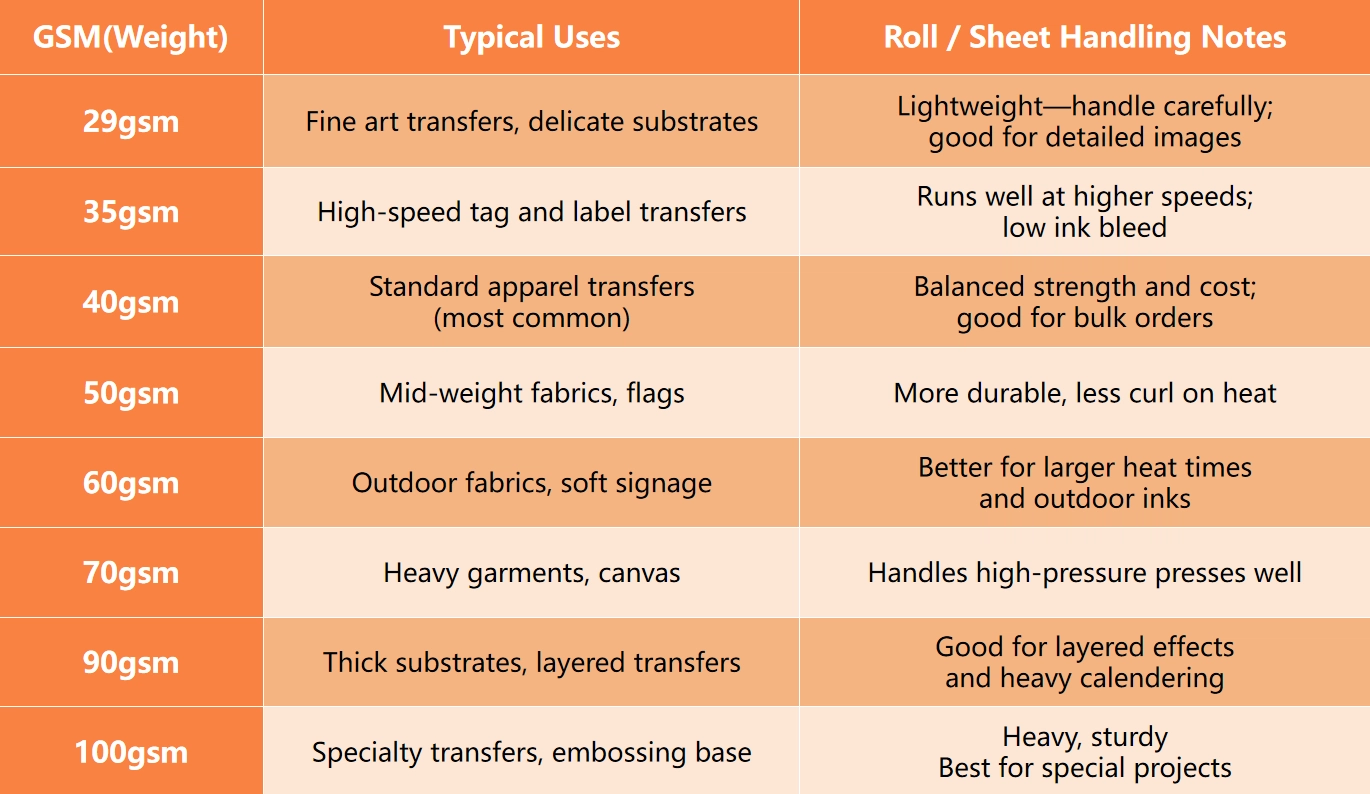

Below is a quick reference table for common gsm weights and recommended use:

Practical tip: keep at least 2–3 rolls of your highest-selling weights (commonly 40gsm and 50gsm) for every 100 orders expected in peak weeks. That simple rule reduces emergency purchases and price spikes.

Ensure You Never Miss a Sales Opportunity

In the peak season, a major sales opportunity often comes unexpectedly—a bulk order from a corporate client, a last-minute request from a retail partner, or a trending product that suddenly goes viral. The greatest frustration is having to turn down these profitable orders simply because your production capacity cannot keep up. This is where a reliable supply of high-speed sublimation paper becomes your strategic asset. Set reorder triggers by combining lead time and weekly usage. For example, if you use 30 rolls of 40gsm per month and supplier lead time is 7 days, maintain a safety stock of at least 10 rolls to cover delays. Small adjustments like this keep your production line moving and avoid disappointing buyers.

チュースe the Right Sublimation Print Products and Supplies

Materials and tools are the foundation for reliable output. Choosing the correct mix of dye sublimation paper, inks, and heat presses reduces variation and increases repeatability. When you match paper weight to substrate, check three factors: transfer temperature/time, ink absorption, and press pressure. Below we summarize key selection criteria and practical suggestions to guide decisions without jargon.

What to Check When Buying

I.Paper compatibility: Make sure your dye sublimation transfer paper is tested with your ink brand and printer model.

II.Heat profile: Different weights need different temperatures; lighter papers usually require slightly lower temp/time pairs.

III.Batch consistency: Purchase paper from consistent production runs to avoid color shifts.

A Short Buying Checklist

I.Verify manufacturer test reports for color gamut and dot gain.

II.Order sample packs (29gsm–100gsm) and run at least 10 test pieces per weight.

III.Track transfer yields (number of acceptable prints per run) to measure supplier performance.

結論

Imagine a Christmas season where orders ship on time, colors stay true across batches, and your customers come back next year. That outcome starts with choosing the right dye sublimation paper and aligning it with dependable sublimation printing supplies. From 29gsm fine-transfer sheets to sturdy 100gsm specialty stock, picking the proper weight matters.

As a leading sublimation paper manufacturer from China, チャンファ デジタル offers a broad range of sublimation transfer papers designed for high-speed production and consistent results. If you want to secure profits and stand out in the high-end holiday shopping market, contact us at 396838165@qq.com. We can provide samples and ensure you get the consumables that will keep your printing press running efficiently and make your customers smile this Christmas.