Venta caliente

-

Papel de transferencia de calor de sublimación no pegajoso de 30Gsm de ventas calientes para los textiles de impresión digital

-

Papel de transferencia de sublimación 35gsm para bufanda de Hijab de impresión digital

-

impresora de tela digital de alta calidad de la máquina de impresión de color digital cmyk (modelo-xplus-8)

-

Impresora de transferencia de calor de la impresora de sublimación de alta velocidad para la impresión digital 5198-8

Phone:+86-15215969856 E-Mail: 396838165@qq.com

Para las empresas de impresión y los profesionales creativos, elegir entre DTF (Direct to Film) y sublimación puede ser confuso: ¿qué sistema de tinta es realmente adecuado para mi trabajo? La respuesta es’ t siempre blanco y negro; Depende totalmente de su tela objetivo, la sensación de mano deseada del producto final y las características específicas de sus pedidos. ¿Estás manejando pequeños lotes de camisetas de algodón o miles de camisetas de poliéster? Comprender las diferencias químicas entre tinta de transferencia DTF y tinta de sublimación de tinte es la única manera de evitar costosos errores de producción y ofrecer los resultados que sus clientes esperan. Vamos’ profundice en la mecánica de estos fluidos para ver cómo definen sus capacidades empresariales. Esta guía compara estos dos enfoques desde una perspectiva básica de la ciencia de la tinta y los requisitos técnicos, ayudándole a tomar una decisión informada para su próximo proyecto.

El núcleo de la impresión DTF y sus demandas de tinta

La impresión DTF ha crecido mucho en fama últimamente porque soluciona un problema con el que las viejas formas tenían problemas: poner impresiones en materiales oscuros y naturales sin mucho trabajo de preparación. Pero el truco real es’ t solamente en la película o el polvo; se reduce a la composición básica de la tinta de impresión DTF. A diferencia de las tintas hechas de tintes, las tintas DTF utilizan pigmentos. Eso significa que tienen pequeños trozos sólidos mezclados en una base líquida. Esta configuración decide cómo funciona la impresora y cómo se toca la transferencia final. Para realizar buenas transferencias de DTF, debe asegurarse de que estas tintas sean más gruesas. Necesitan más cuidado que los tipos de tintes.

El indiEl papel de la tinta blanca

En el mundo de las transferencias DTF, la tinta blanca es la base de todo. Sin ella, usted puede’ t poner huellas en ropa oscura. Eso supera la razón principal para elegir DTF sobre sublimación. La tinta de transferencia DTF blanca funciona como una capa inferior, una capa inicial que va entre la imagen en color y la tela. Hace un fondo sencillo para que los colores sobresalen, incluso en camisas negras o azules oscuros.

Sin embargo, la tinta blanca es también el componente técnicamente más difícil. Contiene dióxido de titanio (TiO)2), un pigmento pesado que naturalmente quiere depositarse en la parte inferior del tanque de tinta. Si una impresora permanece inactiva incluso durante 24 horas, esta sedimentación puede obstruir las boquillas del cabezal de impresión. Las tiendas profesionales que ejecutan grandes volúmenes de transferencias de Navidad DTF saben que un sistema de circulación no es negociable. La tinta debe estar en movimiento constante. Cuando compra tinta de impresión DTF, buscar fórmulas que eviten la rápida sedimentación es clave para mantener su tiempo de inactividad de mantenimiento bajo.

Características clave de las tintas DTF

Al evaluar la tinta personalizada para DTF, necesita mirar más allá de la precisión del color. El comportamiento físico de la tinta a medida que viaja desde el amortiguador hasta la película es lo que determina si un trabajo falla o tiene éxito. La tinta de transferencia DTF de alta calidad debe poseer una fluidez excelente para pasar a través de cabezales de impresión de alta precisión como la Epson i3200 sin hambrar las boquillas durante los modos de impresión rápida.

Yo.Excelente fluidez y estabilidad: La tinta debe ser lo suficientemente viscosa como para no correr sobre la película sino lo suficientemente fluida como para chorrar de manera consistente. Si está imprimiendo 500 impresiones DTF de Navidad en fila, la densidad de la tinta no puede fluctuar. Una fluctuación de hasta el 5% puede causar líneas de banda que arruinan el lote. La estabilidad también significa que la tinta ganó’ t separar en la botella durante el almacenamiento.

II.Mano suave se siente & Durabilidad: Una queja común sobre el DTF temprano fue el “ plástico” sentir. La tinta de impresión DTF moderna y de alta calidad está formulada para unirse firmemente con el polvo fundido en caliente, creando una capa más delgada y transpirable. Esto es crucial para la ropa de moda, donde un parche pesado se siente barato.

III.Amplia compatibilidad: Las mejores transferencias DTF funcionan en casi cualquier cosa: algodón, nylon, cuero y mezclas 50/50. La química de la tinta está diseñada para ser químicamente inerte con respecto al sustrato; se basa en el polvo para la adhesión, haciendo de la tinta en sí un portador versátil de color para casi cualquier proyecto.

La ciencia de la sublimación de la tinta y la fusión de la tela

Mientras que DTF se sienta en la parte superior, la sublimación va más profundo. El proceso de sublimación del tinte es fundamentalmente diferente porque es una reacción química que une el color a la fibra a nivel molecular. Esta sección explora por qué la tinta de sublimación de tinte sigue siendo el rey del desgaste de rendimiento de poliéster y sustratos duros. No se trata solo de imprimir; Se trata de teñir.

La transición del sólido al gas sin convertirse en líquido es lo que define “ sublimación. ” Este cambio de fase único requiere tintas que son químicamente distintas de las tintas de pigmento usadas en DTF. Para los propietarios de tiendas, entender esta ciencia explica por qué puede’ t simplemente poner la tinta de sublimación en una impresora DTF, o viceversa. Los requisitos para calor, presión y tiempo son estrictos, y la formulación de la tinta debe alinearse perfectamente con estos parámetros para lograr que “ tatuaje-como” permanencia en el tejido.

¿Cómo funciona la tinta de sublimación?

La tinta de sublimación de tinte está compuesta por partículas de tinte sólido suspendidas en agua. Cuando se imprime en papel de transferencia, la tinta se seca como un sólido. La magia ocurre en la prensa de calor, generalmente alrededor de 380 ° F a 400 ° F (193 ° C y 204 ° C). A esta temperatura específica, el tinte sólido se convierte en un gas. Simultáneamente, los poros poliméricos de la tela de poliéster se abren como una flor al sol.

La nube de gas del tinte permea estos poros abiertos. Cuando se elimina el calor, los poros se cierran, atrapando el tinte dentro de la fibra. Esta es la razón por la que las impresiones de sublimación nunca se agrietan o se pelan: la tinta es ahora parte de la camisa. A diferencia de las transferencias DTF, que agregan una capa, la sublimación agrega cero peso a la prenda. Este mecanismo es el estándar para camisetas de ciclismo y ropa activa, donde la transpirabilidad es la prioridad número uno.

Requisitos críticos para las tintas de sublimación

No todas las tintas de sublimación se crean iguales. Si está buscando resultados de gama alta, específicamente con productos como la serie Color CMYK 1983 de Changfa, necesita mirar la pureza y el tamaño de partículas. Las tintas de baja calidad a menudo tienen partículas más grandes que pueden causar dos problemas principales: boquillas obstruidas y resultados de transferencia granulada en el producto final.

I. Alta pureza y tamaño de partículas finasPara pasar a través de cabezales de impresión modernos, las partículas de tinte en tinta de sublimación de tinte generalmente necesitan ser filtradas a menos de 0,2 micras (aproximadamente 1/300 de la anchura de un cabello humano). La serie de 1983 de Changfa, por ejemplo, se somete a una filtración en tres etapas. Esto evita que “ efecto de papel lija” dentro de la boquilla, extendiendo significativamente la vida útil de su cabezal de impresión.

II. Videz del color y velocidad de transferenciaUna buena tinta es’ t solo sobre lo que se ve bien en papel; es’ sobre lo que se libera en la tela. Las tintas de alta calidad tienen una alta tasa de transferencia, lo que significa que menos tinta queda en el papel residual y más va a la camisa. Esto hace que los negros sean más profundos y los rojos más brillantes, lo que es vital para diseños de alto contraste.

III. Limitación materialEs importante recordar la limitación: esta química solo se une con polímeros. El algodón no tiene poros que se abren con el calor para atrapar el gas. Por lo tanto, mientras que la tinta de transferencia DTF funciona en algodón, la sublimación requiere estrictamente superficies de poliéster o polirecubiertas.

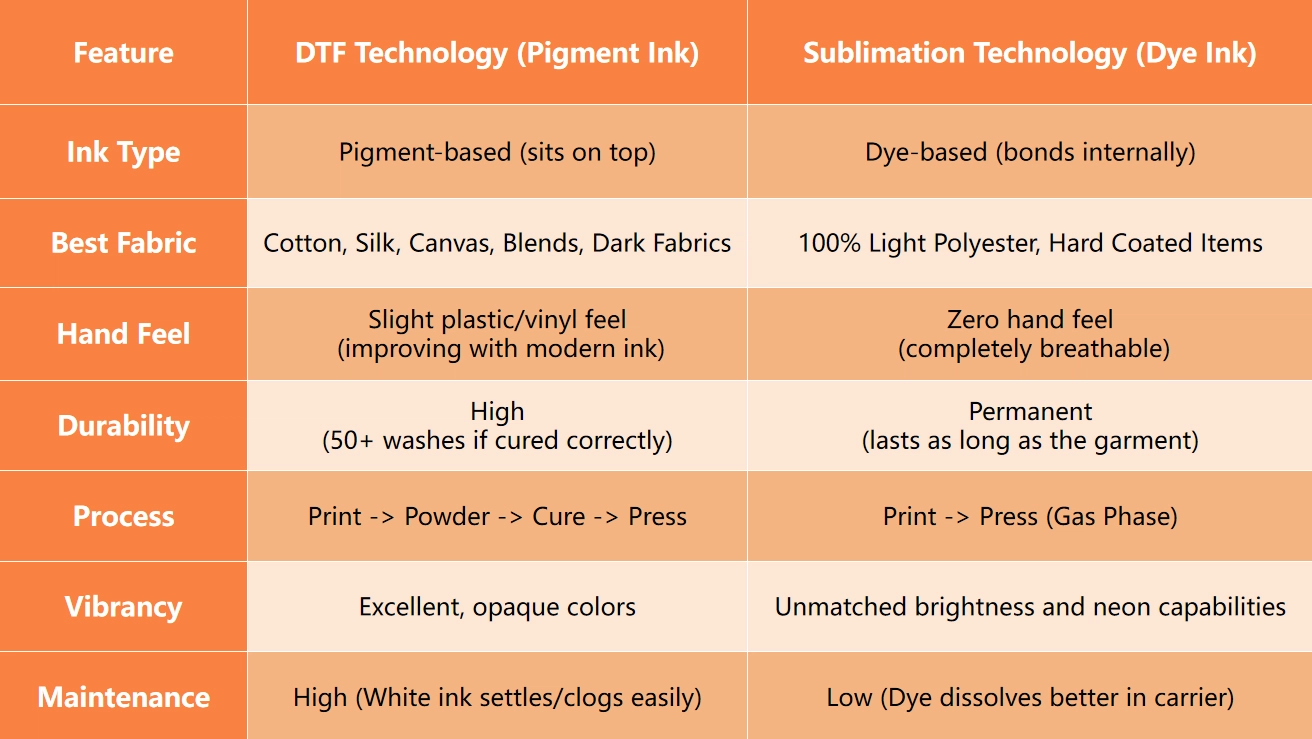

Comparación paralela para la toma de decisiones informada

Ahora que entendemos la ciencia detrás de los líquidos, veamos la aplicación práctica. Cuando planea su inventario para la temporada navideña, tal vez prepare transferencias de Navidad DTF junto con tazas personalizadas, necesita conocer el costo, el tiempo y las implicaciones de calidad de cada método. Una comparación directa aclara dónde gana cada tipo de tinta.

Para un empresario, la decisión a menudo se reduce a “ Costo vs. Versatilidad” debate. ¿Invertes en un sistema que hace trabajos específicos perfectamente (sublimación) o en un sistema que hace todo bastante bien (DTF)? La tabla siguiente desglosa las realidades operacionales del uso de tinta de impresión DTF frente al fluido de sublimación en un entorno de producción del mundo real.

Changfa Digital’ s Soluciones de tinta a medida

Conseguir un vendedor constante es tan importante como elegir la tecnología adecuada. Grupos de tinta desiguales pueden dañar su nombre. Changfa Digital ha puesto años fijando mezclas para solucionar los problemas exactos mencionados anteriormente, desde agujeros atascados hasta tonos desvanecidos. Si necesita tinta personalizada para una máquina determinada o hace líquidos regularmente, el control superior es clave.

Changfa ofrece un conjunto fuerte construido para mantener sus impresoras funcionando y sus compradores contentos. Entendemos que si imprimes una foto familiar o 5.000 impresiones DTF de Navidad, el resultado debe ser exacto cada vez. Aquí están los detalles de nuestras dos líneas principales de tinta hechas para lugares de impresión profesional.

Tinta de pigmento de la serie CF-DTF

Nuestra tinta de impresión DTF está diseñada para resolver el mayor dolor de cabeza de la industria: la obstrucción de la cabeza. Utilizamos una tecnología única de encapsulación de resina que mantiene las partículas de pigmento lisas y suspendidas. Esto significa que puede dejar su impresora por períodos más largos sin despertarse a una cabeza de impresión seca.

Además, el Serie CF-DTF está formulado para alta capacidad de estiramiento. Cuando creas transferencias DTF para ropa deportiva o telas elásticas, nuestra tinta se mueve con el material en lugar de agrietarse. Proporciona una excelente cobertura, lo que significa que utiliza menos tinta blanca para obtener un fondo sólido, reduciendo efectivamente su costo por impresión mientras mantiene esa sensación de mano suave y premium.

Tinta de sublimación de tinte de la serie CF-Sub

Para aquellos dirigidos al área de poliéster, el Color CMYK Serie 1983s cambia las cosas. Esta tinta de sublimación de tinte está configurada para ejecuciones rápidas y trabajo constante. Eligimos las materias primas superiores de los principales vendedores mundiales para asegurarnos de que la gama de colores sea amplia y verdadera.

La serie de 1983 golpea el “ velocidad de movimiento” problemas duros. Muchas tintas de bajo costo dejan el 40% de la sombra en el papel. Nuestra mezcla promete una tasa de movimiento superior al 98%, por lo que obtienes negros más profundos y rojos más vivos mientras usas menos tinta. Funciona con cabezales de impresión grandes como Epson, Mimaki y Mutoh. El flujo suave se comprueba para prometer una impresión continua, lo que le permite hacer turnos nocturnos para grandes pedidos sin miedo a la falta de tinta o rayas.

Conclusión

Elegir entre estas dos tecnologías no’ Tiene que ser una apuesta. Si tu trabajo gira en torno a camisetas 100% algodón, sudaderas de colores oscuros, o necesitas la versatilidad para imprimir en denim y cuero, el sistema de tinta de transferencia DTF es tu competidor más fuerte. Abre la puerta para producir las mejores transferencias DTF para cualquier cliente que pase por su puerta.

Sin embargo, si su negocio se centra en ropa deportiva de rendimiento, artículos promocionales como tazas y almohadillas de ratón, o está buscando estampados sin costuras y transpirables que nunca se desvanecen, entonces tradicionales tinta de sublimación de tinte Es la elección superior. Su capacidad de unión a nivel molecular ofrece una calidad que las tintas de pigmento simplemente no pueden replicar en el poliéster.

Su negocio probablemente tenga espacio para ambos, pero empezar con la tinta adecuada es el primer paso para ganar dinero. No’ t deje que los líquidos malos ralenticen su línea de fabricación. Alcanzar Changfa Digital hoy en 396838165@qq.com para hablar de sus necesidades exactas. Déjanos ayudarle a encontrar el mejor ajuste para su equipo y elevar su negocio de impresión.