HOT SALE

APPLICATION

Phone:+86-15215969856 E-Mail: 396838165@qq.com

When you print on polyester, the real challenge is not whether color can be transferred. Both sublimation and heat press methods can produce acceptable results in controlled tests. The real question is which method holds up once durability, fabric feel, production scale, and long-term efficiency are considered.

If you work with polyester regularly, you already know that heat is involved in both processes. What differs is how heat interacts with the material and how the final image becomes part of the fabric—or remains on its surface. This article examines sublimation and heat press from a production and lifecycle perspective, helping you decide which method aligns better with your specific polyester application.

Who Is Changfa Digital, and Why Does Its Material System Matter When Comparing Printing Methods on Polyester?

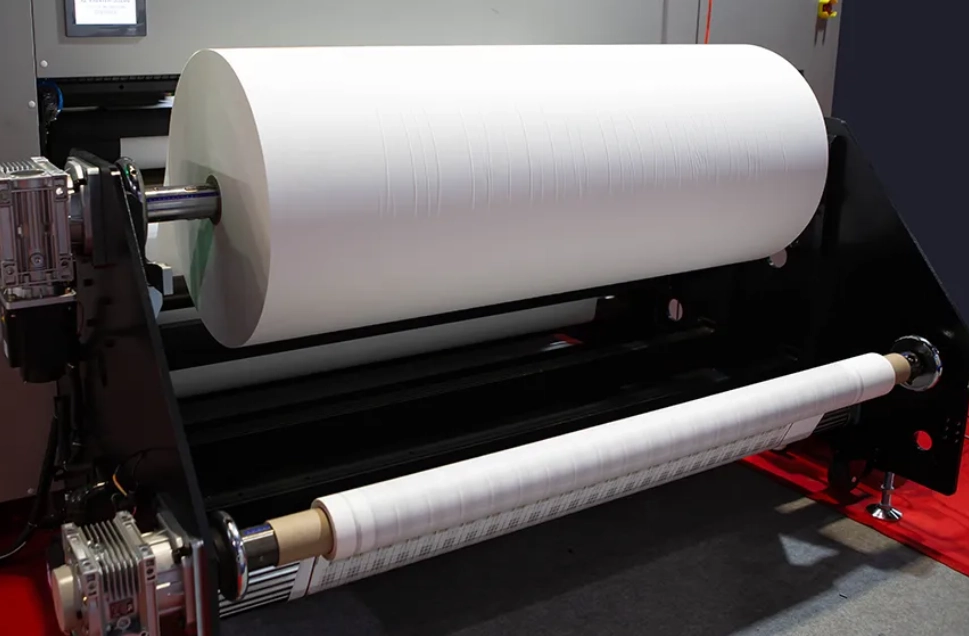

Changfa Digital is a long-established manufacturer focused on sublimation paper production and digital printing services, with more than 15 years of experience serving polyester-based textile workflows. Unlike suppliers that rely on outsourced processing, Changfa Digital works as a full-scale factory, covering base paper selection, coating, precision slitting, and export packaging within a single production system.

We run four coating lines, four slitting workshops, and ten cutting machines, producing up to 3,000 tons of sublimation paper each month and exporting about 120 containers worldwide. This volume counts when assessing sublimation printing as an approach instead of a sample-based technique. Stable coating performance, controlled paper weight, and consistent roll shape reduce differences when shifting from small batches to continuous production.

From a practical standpoint, Changfa Digital’s material system is built around how sublimation behaves on polyester under real heat, speed, and ink-load conditions. That makes it relevant when you compare sublimation—which depends heavily on paper performance—to heat press methods that rely on surface bonding.

What Is the Fundamental Difference Between Sublimation and Heat Press When Applied to Polyester?

Though both methods use heat, they connect with polyester in quite different ways.

How dye penetration versus surface adhesion defines durability, feel, and visual integration

Sublimation works by turning solid dye into a gas under heat, making it spread into polyester fibers at a molecular level. Once cooled, the dye turns into a part of the fiber structure. In contrast, Heat press printing puts a design coat, such as vinyl or film, onto the fabric surface by using adhesive activation.

This distinction defines everything that follows—durability, breathability, texture, and long-term appearance. Sublimation integrates color into the fabric, while heat press places color on top of it.

How Does Sublimation Actually Perform on Polyester in Long-Term Use?

Sublimation tends to be selected for polyester since the material matches the process in terms of chemistry.

Why sublimation delivers consistent color, soft hand feel, and wash resistance on polyester

When sublimation parameters are controlled, the color turns lasting inside the fiber. There is no breaking, peeling, or added stiffness because no surface layers form. The fabric maintains its breathability and drape, which explains why sublimation is widely used in sports clothes, performance apparel, and large-area designs.

After many washes and stretches, sublimated prints tend to fade gradually instead of breaking down. This pattern makes performance predictable over the cloth’s lifespan.

What Role Does Sublimation Paper Play in Achieving Reliable Results on Polyester?

Sublimation is not only about ink and heat. Paper behavior directly affects transfer quality.

How paper weight and coating behavior affect ink release and transfer efficiency

Sublimation paper must hold ink during printing, then release it efficiently under heat. Paper that releases too quickly causes color instability, while paper that holds ink too tightly reduces transfer efficiency.

A 40 gsm sublimation transfer paper is often used as a balanced option for general polyester printing, offering controlled ink absorption and stable release without sacrificing speed. This weight supports consistent color transfer across a wide range of polyester fabrics and production speeds.

Paper consistency becomes especially important when you scale production, as variations in coating or gsm directly affect color output and waste rates.

How Does Heat Press Printing Perform on Polyester Compared to Sublimation?

Heat press printing serves a different purpose and solves different problems.

Why heat press methods offer flexibility but introduce surface-related limitations

Heat press printing allows you to apply designs to many fabric types, including blends and dark colors that are unsuitable for sublimation. Besides, it also supports special effects such as layered graphics or raised textures.

However, as the design rests on the surface, heat press prints often feel thicker and reduce the airflow of the fabric. Over time, surface layers may crack, peel, or show border damage, especially on clothes that stretch or flex frequently.

What Durability Differences Appear Between Sublimation and Heat Press Over Time?

Initial appearance can be misleading when evaluating durability.

How washing, stretching, and abrasion expose structural differences between the two methods

Sublimated prints typically maintain integrity because there is no physical layer to fail. Color loss happens gradually and evenly. Heat press prints, by contrast, face a greater chance of machine failure. Repeated washing and rubbing can weaken adhesion, leading to peeling or visible damage. If the use involves frequent cleaning or constant movement, these differences are important.

When Does Heavier or Fast-Dry Sublimation Paper Become More Advantageous?

Why higher gsm and fast-dry paper improve stability in dense or high-speed sublimation workflows

In applications with high ink coverage, deep colors, or fast production speeds, heavier or fast-dry sublimation paper can improve control. Increased gsm provides better ink holding capacity and reduces the risk of smudging before transfer.

A 70 gsm fast-dry sublimation paper is often selected for dense graphics, monument printing, or blankets where ink load is high, and stability matters more than material cost.

Which Method Handles Large-Scale Production on Polyester More Reliably?

Which Method Handles Large-Scale Production on Polyester More Reliably?

Scale changes the economics and risks of printing methods.

How process stability, repeatability, and waste control differ between sublimation and heat press

Sublimation scales efficiently because it integrates well with roll-to-roll printing and continuous heat transfer. Once parameters are stabilized, repeatability is high, and labor input per unit is low.

Heat press printing becomes more labor-intensive as volume increases. Manual handling, alignment, and press cycles introduce variability that is harder to control at scale.

What Common Mistakes Do People Make When Choosing Between Sublimation and Heat Press?

Many decisions are made for the wrong reasons.

Why choosing based only on equipment cost or setup speed leads to long-term inefficiency

A common mistake is choosing a heat press because the initial equipment cost appears lower, without considering labor, rework, and durability. Another is avoiding sublimation because it seems complex, even though it may offer a lower cost per unit at scale. The correct choice depends on total production cost, expected lifespan of the print, and fabric performance requirements.

Which Printing Method Actually Works Better for Your Polyester Application?

Sublimation and heat press are not competitors solving the same problem. Sublimation excels when durability, fabric feel, and production scale matter. Heat press supplies flexibility and versatility for small batches, special effects, or mixed materials.

The approach that performs better tends to match the polyester fabric, quality expectations, and the way of producing and delivering the final product.

FAQs

Q: Is sublimation always better than heat press for polyester?

A: No. Sublimation is superior for durability and fabric integration, while heat press is useful for small batches or special designs.

Q: Why does heat press printing sometimes feel stiff on polyester?

A: Because the design forms a surface layer that alters the fabric’s texture and airflow.

Q: Can sublimation and heat press be used together in one workflow?

A: Yes. Many operations use sublimation for base graphics and heat press for personalization or accents.

Which Method Handles Large-Scale Production on Polyester More Reliably?

Which Method Handles Large-Scale Production on Polyester More Reliably?