HOT SALE

APPLICATION

Phone:+86-15215969856 E-Mail: 396838165@qq.com

If you’re knee-deep in the world of custom printing—whether it’s for t-shirts, mugs, or even those quirky promotional items—you’ve probably heard the buzz around DTF film transfer and sublimation heat transfer. Both are game-changers for getting vibrant designs onto fabrics and other surfaces. But picking the right one? That’s where things get tricky. Costs add up fast, materials don’t always play nice, and you want colors that pop without fading after a few washes. In this post, we’ll dig into the nitty-gritty differences between DTF (that’s Direct to Film) and sublimation printing. We’ll cover everything from upfront expenses to how they hold up in real life. By the end, you’ll have a clearer picture of what fits your projects best. And if you’re leaning toward sublimation, brands like Changfa Digital could be your go-to for top-notch supplies—more on that later.

What Are DTF Film Transfer and Thermal Sublimation Printing?

Before we jump into comparisons, let’s get the basics straight. You can’t make a smart choice without knowing what each tech brings to the table. I’ve been tinkering with these methods for years, and trust me, skipping this step leads to wasted ink and frustration.

DTF Film Transfer

DTF film transfer starts with printing your design onto a special film using pigment inks. Then, you sprinkle on DTF adhesive powder that sticky stuff that melts under heat, and shake off the excess. Heat it up, and boom, you’ve got a transferable decal ready to press onto almost anything. It’s like making your own iron-on, but way more pro.

What makes DTF stand out? Flexibility. You can slap it on cotton, polyester, blends, even leather or wood sometimes. Dark fabrics? No problem; the white underbase handles that. I remember once printing a batch of hoodies for a local band—deep navy blue ones—and DTF nailed the bright reds without any bleed. Costs for DTF film powder and the film itself vary, but you can find reliable DTF film suppliers who bundle them cheaply if you’re buying in bulk. Setup’s straightforward too: a decent printer, a heat press, and you’re off. Just watch out for the powder mess; it gets everywhere if you’re not careful.

Thermal Sublimation Printing

Thermal sublimation printing, on the other hand, uses dye inks that turn into gas when heated, bonding right into the material’s fibers. No films or powders here—just print on sublimation paper, press it face-down on your item, and let the magic happen. The result? Designs that feel like part of the fabric, not stuck on top.

It’s picky about materials, though. Works best on polyester or poly-coated stuff, and light colors are a must for vivid results. Sublimation skips the extra steps of DTF, but you need a sublimation-specific printer. And don’t forget: once it’s printed, there’s no going back if you mess up the alignment.

Changfa Digital specializes in high-quality sublimation paper that ensures even ink transfer—no blotches or ghosts. They’ve been in the game for over a decade, cranking out rolls from their factories with German tech for precision coating. If you’re sourcing, their site has all the specs on paper weights and sizes.

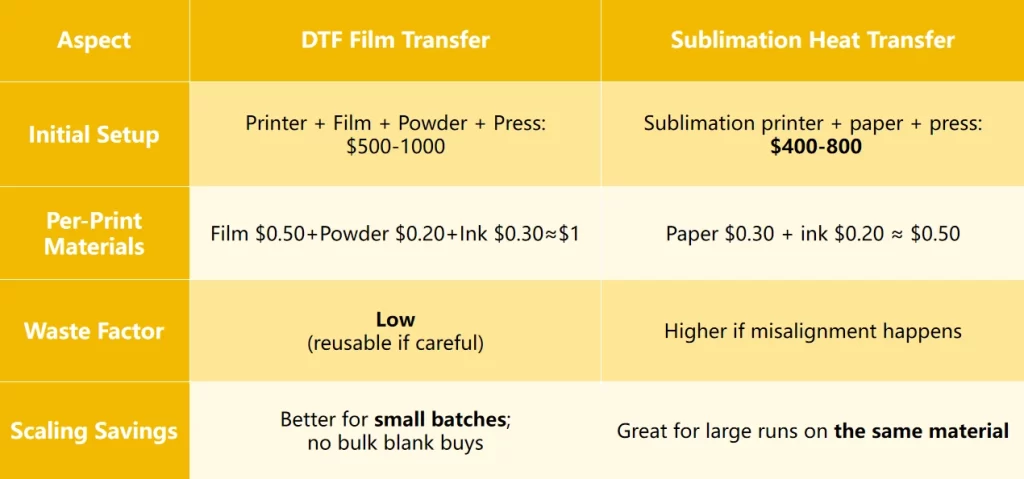

Cost Analysis: Which Method Offers Better ROI?

Let’s crunch some numbers on costs because that’s often the deal-breaker for small shops or hobbyists scaling up.

DTF can seem pricier at first glance. The DTF film printing setup includes the film (around $0.50-$1 per sheet for A3 size), DTF hot melt powder ($10-15 per kilo, lasting for dozens of prints), and inks. Factor in a heat press if you don’t have one—decent ones start at $200. But here’s the win: low waste. You print only what you need, and it works on various items, so no special blanks are required. For a run of 100 t-shirts, you might spend $2-3 per shirt in materials, dropping with volume.

Thermal sublimation printing offers a cost-effective solution with cheaper inks and paper compared to other methods. Sublimation paper typically ranges from $0.20-0.40 per sheet. The total per-item cost for printing 100 polyester shirts could be around $1-2. However, polyester blanks are pricier than cotton, costing about $5 per shirt compared to $3 for cotton. For mugs or hats, additional coatings or specialized equipment are needed, increasing overall costs.

Which Materials Work Best?

Materials make or break a print job. Pick wrong, and your design peels off after one wash. Let’s break this down.

DTF shines on cottons, dark colors, and tricky surfaces. The DTF film powder creates a bond that sticks to natural fibers without pretreatment. Cotton tees, hoodies, even denim—DTF handles them all. Deep blacks or navies? The white base layer ensures colors pop.

But it’s also not perfect. On super stretchy stuff like spandex, it might crack over time. But for mixed fabrics, it’s a champ. If you’re sourcing DTF film transfer supplies, look for compatible powders that melt at lower temperatures to avoid scorching delicate items.

Sublimation demands polyester or blends with at least 50% poly content. Light colors only, or you’ll get muddy results on darks. Great for sportswear, banners, or hard goods like phone cases with poly coatings. The dyes infuse into the fibers, so the fabric feels smooth as silk.

What about the downside? Cotton is a no-go because the dyes won’t bond. Therefore, stick to white or pastel poly fabrics for the best vibrancy. Changfa Digital’s sublimation papers are optimized for this, with fast-dry coatings that prevent ink bleed on poly fabrics.

Colors are why we print, aren’t they? DTF delivers bold, opaque hues thanks to the pigment inks and white base. Think metallic effects or neons on dark backgrounds—stunning for streetwear. But sometimes, the edges feel a tad raised, like a thin layer. Thermal sublimation printing shows the unmatched vibrancy on light poly. Colors are embedded, so the photos come out lifelike with no cracking. However, on anything but white, you lose punch.

How Long Will Your Prints Last?

Durability matters, especially for wearables or items that see heavy use. Nobody wants a design peeling off after a few washes or fading under the sun. Here’s how DTF film transfer and sublimation heat transfer stack up in the long haul to help you plan.

DTF Durability: Tough but Needs Care

DTF prints are built to last, thanks to the DTF hot melt powder creating a strong adhesive bond. When cured properly—think 160°C for 15 seconds on a heat press—they can survive 50+ washes on cotton or blends. The white underbase in DTF film printing keeps colors vivid, even on dark fabrics, without cracking under normal wear.

But there’s a catch. High-heat dryers or aggressive detergents can stress the adhesive, leading to peeling edges over time. Stretchy fabrics like spandex? They might show micro-cracks if overextended. To maximize life, wash inside out, cold water, and air dry when possible. Also, quality matters—using premium DTF adhesive powder from a trusted DTF film supplier like Changfa Digital ensures better adhesion. Their powders are formulated for even melting, reducing weak spots.

Sublimation’s Longevity: Near-Permanent on Polyester

Sublimation is the king of durability on polyester or poly-coated items. Since the dye infuses into the material’s fibers, there’s no layer to peel or crack. UV resistance is another win. Sublimation on outdoor banners or flags holds up for years without fading, even in harsh sunlight.

On hard goods like mugs or phone cases, it’s practically bulletproof, provided the poly coating is solid. But the catch is only as good as the material. Low-poly blends or improper coatings lead to washout—my early mistake with a cheap blended shirt taught me that. Stick to high-polyester blanks and use quality sublimation paper from suppliers like Changfa Digital, whose papers ensure over 98% ink transfer for lasting vibrancy.

In short, DTF is tough for versatile applications but needs tender loving care. Sublimation is near-indestructible on the right materials. Choose based on your project’s wear and tear.

Conclusion

So, how do you choose? Assess your projects. Lots of cotton or darks? Go DTF—grab quality DTF film printing gear to keep costs down. Poly-focused with big runs? Sublimation’s efficiency wins. Consider your setup, too. Limited space? Sublimation needs less mess. Budget tight? Start with DTF for broader applications.

If you are interested in thermal sublimation printing or DTF film transfer, check out Changfa Digital. As a professional DTF film supplier alternative for sublimation, we offer premium papers that boost transfer rates up to 98% ink efficiency. And our global shipping and factory-direct prices will make scaling easy. Regardless of which technology you ultimately choose for your specific project, Changfa Digital is your trusted partner. We invite you to explore our product line and experience firsthand the difference high-quality materials make.

Contact our experts today at 396838165@qq.com to learn more about our DTF film and sublimation solutions, and receive samples to make the most informed choice for your business!