HOT SALE

APPLICATION

Phone:+86-15215969856 E-Mail: 396838165@qq.com

If you have ever stepped into a small shop and admired the bright, detailed images on a polyester team uniform or a coffee cup, you have witnessed the wonder of digital fabric printing. This field has grown quickly in recent times. Yet, along with that expansion comes a key concern that plenty of beginners and company owners are raising: Is sublimation ink toxic? In our current time, people pay close attention to the substances in their clothes and the air around them. So, it is essential to know what is inside your printing device. No matter if you run a tiny online store from your home office or handle a big manufacturing setup, grasping the gap between risky materials and a solid, harmless sublimation ink can transform your daily operations. In this overview, we will explain the science behind it, the effects on the surroundings, and the reason picking the best sublimation ink supplier stands out as your top choice for well-being and the earth.

Breaking Down the Myths About Ink Safety

For many years, the printing business carried a bad image. Old-fashioned solvent-based inks were well-known for holding heavy elements such as lead, cadmium, and mercury. Those earlier inks gave off sharp, unpleasant smells and Volatile Organic Compounds (VOCs). These could trigger headaches and breathing problems for employees. Due to this past, lots of folks think that dye-sublimation ink must bring the same dangers. But the methods in today’s digital printing have seen a huge shift toward being more earth-friendly.

Now, the usual type for expert-level sublimation ink is a formula based on water. Unlike those solvent types that depend on tough chemicals to move the color, current sublimation dyes float in a water mix. This change has almost wiped out the worst poisons from the whole procedure. When you pick an environmentally friendly sublimation ink, you safeguard not only the person using it. You also make sure the finished item—like the top or the throw—stays safe for buyers, including infants and those with delicate skin.

Contrast Between Traditional Inks & Modern Sublimation Dyes

Traditional offset or solvent printing often leaves a chemical residue on the surface of the material. In contrast, the sublimation process is a “dry” technology at its core. When heat is applied, the dye sublimation ink turns from a solid into a gas and bonds directly with the fibers of the fabric. Once this process is complete, the ink is “locked” inside the material. It doesn’t flake off, it doesn’t wash out, and it doesn’t leave a toxic layer on the surface.

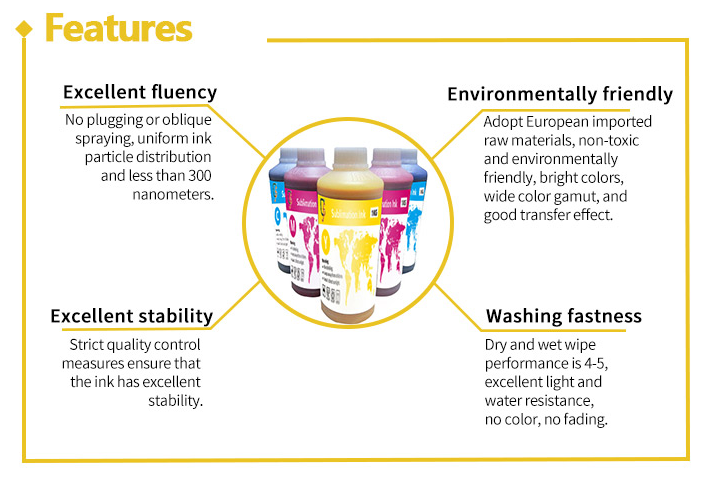

This is where the concept of a non-toxic sublimation ink becomes so important. While traditional inks might contain 50% or more VOCs, a high-quality water-based sublimation ink usually contains zero or negligible amounts. At Changfa Digital, for instance, we’ve focused on creating formulas that achieve a 98% or higher transfer rate, meaning less waste and fewer chemicals floating around your workspace. This level of safety makes it a preferred choice for the digital textile printing industry, which is under constant pressure to meet strict global safety standards.

How To Identify “Green” Certifications

If you seek a trustworthy sublimation ink supplier, do not just accept their claims. Check for actual proof and approvals. The leading global benchmark is the Oeko-Tex Standard 100. An ink with this approval has gone through tests for more than 100 dangerous items. Leading sublimation ink manufacturers often show these approvals openly. They are costly and hard to obtain.

When an ink is called an environmentally friendly sublimation ink, it generally signals that it lacks APEOs (Alkylphenol ethoxylates) and formaldehyde. These substances appeared often in textiles for years. But now, many nations ban them because of their bad effects on body’s hormones and nature. Selecting a certified non-toxic sublimation ink helps secure your company against stricter eco rules coming soon.

Why Changfa’s Sublimation Ink is the Safe Choice

As a dedicated sublimation ink supplier, Changfa Digital has spent years refining the chemical balance of our products. We believe that “vibrant color” and “eco-safety” should never be mutually exclusive. Many cheap inks on the market use low-grade pigments that require more chemical additives to stay stable in the bottle. This can lead to printhead clogging and, more importantly, the release of unpleasant fumes during the heat-pressing stage.

Our high-quality dye sublimation color ink is engineered to be odor-free and highly stable. We use high-purity dyes that have been filtered through a 0.2-micron system, ensuring that the sublimation ink flows smoothly without the need for aggressive chemical solvents. This makes our ink a staple for professional digital textile printing setups where 24/7 production is the norm.

Achieving Superior Color Without Toxic Additives

The key to what we do well comes from the strength of the pigments. Since our dye sublimation ink packs more color material, you need smaller quantities to get the same strong look. In truth, many customers mention cutting ink use by 15% over cheaper options. Cutting back on ink does more than save money. It boosts safety too. With less ink on the sheet, fewer vapors escape when the press reaches 200°C (392°F).

As one of the top sublimation ink manufacturers, we also stress the “cleanness” of the black and cyan dyes. These are usually the trickiest to make without metal-based stabilizers. Our non-toxic sublimation ink delivers a bold, true black. It avoids turning brownish or greenish. This shows that earth-friendly chemistry can beat out older, additive-filled methods. That dependability is why experts rely on us. They need an environmentally friendly sublimation ink that holds up during tight schedules.

Impact on the Workplace and Worker Health

If you once worked in a print place using outdated solvent inks, you recall the odor. It feels sharp, sugary, and thick. During a full workday of eight hours, those smells can cause “printer weariness.” Switching to a water-based sublimation ink clears up the air in the space a great deal. We still suggest good airflow for any heating task. However, the dangers tied to a water-based dye sublimation ink drop way down.

We value the well-being of the person operating the machine as much as the print’s standard. Our goal as a sublimation ink supplier is to offer a product that lets you operate in a pleasant, secure setting. Using non-toxic sublimation ink cuts the chances of skin rashes and lung problems over time. In a field like digital textile printing, where staff handle materials all day, this focus on safety forms the base of a lasting business plan.

The Future of Digital Printing: Sustainability First

The direction is obvious: society heads toward a reuse-based economy. Shoppers now scan tags for “Eco-Safe” or “Bio-Based” options. Soon, the companies you create for will request evidence that your sublimation ink avoids harm. Saying you use an environmentally friendly sublimation ink is not just extra anymore. It turns into a strong sales point that can land premium deals.

As one of the top sublimation ink manufacturers, Changfa Digital already develops the coming wave of dyes. These use even slimmer resources. We take pride in joining the fight for the fabric sector’s waste issues. By swapping out heavy, water-guzzling classic dyeing for exact, water-based digital textile printing, we aid in preserving millions of gallons of water each year.

Reducing Your Environmental Footprint

Classic fabric dyeing causes roughly 20% of the worldwide factory water dirt. Sublimation printing, by comparison, uses almost no water. The main leftover is the transfer sheet. And that is getting easier to recycle. With a high-output sublimation ink, you reduce the chemical trash heading to dumps and seas.

Each container of dye sublimation ink from Changfa marks progress toward a purer field. We supply more than just ink. We offer a route for firms to expand with care. If you wish to shift to a non-toxic sublimation ink that gives top-tier colors, feel free to contact us. Our team stands ready to guide you in selecting the ideal environmentally friendly sublimation ink for your machine and base material.

Conclusion

So, is sublimation ink toxic? The response hinges fully on its standard and origin. While bargain, unapproved inks may still hold bits of bad VOCs or heavy metals, the current field norm moves to non-toxic sublimation ink. This keeps safety for both the maker and nature. By teaming with a trusted sublimation ink supplier like Changfa Digital, you gain lively, pro-level outcomes without giving up health. Our pledge as one of the top sublimation ink manufacturers ensures we keep creating with environmentally friendly sublimation ink solutions. Do not allow safety worries to slow your company. Reach out to us today at 396838165@qq.com to commit to the coming era of digital textile printing. See how pure, eco-aware ink changes things.