HOT SALE

APPLICATION

Phone:+86-15215969856 E-Mail: 396838165@qq.com

Want to jump into textile printing without dropping a ton of cash upfront? Inkjet sublimation transfer paper’s your ticket. It’s changed the game for small and medium shops, dishing out top-notch prints, quick turnarounds, and working with all sorts of materials. This article breaks down how it stacks up against old-school methods and shows how it can keep your workflow smooth while still cranking out pro-level results.

Inkjet Sublimation Transfer Paper

Inkjet sublimation transfer paper is built to carry special dyes from your printer to polyester fabrics or coated hard stuff using heat and pressure. It’s got a slick coating that holds the ink steady until you crank up the heat—around 180–200°C. That’s when the ink turns to gas and fuses right into the material for good. Unlike vinyl or screen printing, which mess around with glues or extra steps, sublimation’s all about heat and pressure. No gunk, no weird texture left behind. Perfect for soft stuff like sports gear or cozy home textiles.

Operational Advantages for Print Businesses

Choosing inkjet sublimation transfer paper can significantly improve your operational efficiency across multiple fronts.

Streamlining Production Workflow

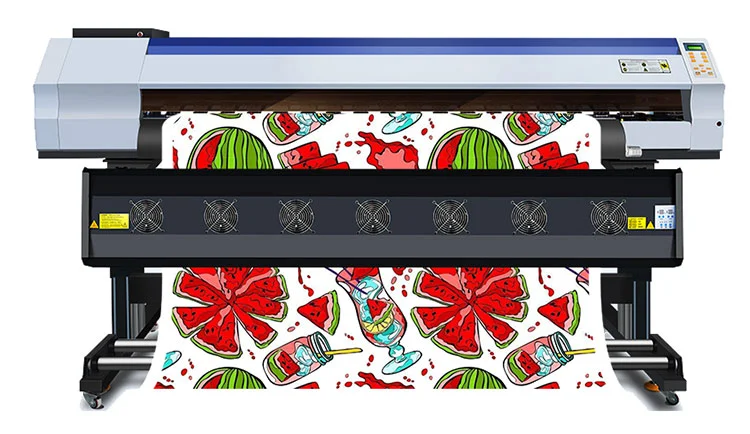

The simplicity of the sublimation process reduces the number of production stages. You don’t need to fuss much from digital design to the finished product. Less hands-on work means cranking out more jobs faster. This allows you to produce more jobs in less time, especially when using automated systems such as the Sublimation Transfer Paper Digital Printer CF-2000, which is optimized for high-volume digital printing.

Reducing Material Waste and Downtime

Since you print designs digitally before slapping them onto the fabric, you dodge messy alignment issues or ink bleed that old-school methods often deal with. That cuts down on wasted materials from trial runs or do-overs. Plus, no screens or plates means you can switch between jobs in a snap, no waiting around.

Enhancing Color Accuracy and Consistency

Digital control ensures that color profiles remain consistent across batches. Sublimation inks offer vibrant hues and deep blacks that maintain fidelity over time. Wide color gamut, vivid color, including a substantial increase in the black coverage of the professional black of sublimation ink after transferring, makes this method ideal for brand-sensitive applications.

Cost Efficiency and Scalability

One of the key reasons many startups choose sublimation over other methods is its affordability without compromising on quality.

Lower Initial Investment Compared to Other Printing Methods

You don’t need expensive screens or specialized dryers as required in screen printing. A basic setup includes an inkjet printer compatible with sublimation inks, heat press equipment, and high-quality transfer paper.

Supporting Small-Batch and On-Demand Production

Because there’s no need for physical templates or dies, you can easily run small orders profitably. This flexibility allows you to cater to niche markets or personalized products without overextending your resources.

Simplifying Equipment Requirements

Fewer machines mean fewer maintenance costs and lower energy consumption. With compact solutions like the CF-2000 Digital Printer, even limited workspaces can support robust production lines.

Application Versatility Across Substrates

The adaptability of inkjet sublimation technology makes it suitable for diverse product categories.

Compatibility With Polyester Fabrics and Coated Surfaces

Sublimation shines on polyester fabrics or stuff coated with polymers, since those dyes really stick when you heat things up. After printing, your textiles hold up great—Sunproof Level 6, Washproof Level 4–5. They stay tough even after a ton of washes or heavy use.

Expanding Product Lines: Apparel, Home Decor, Hard Goods

From custom sportswear to mugs, mousepads, curtains, and signage—the possibilities are extensive. You can scale your offerings based on market demand without investing in new machinery for each category.

Integrating Changfa Digital’s Sublimation Solutions

If you’re seeking a reliable partner in this space, consider working with Changfa Digital. With over 15 years of experience as a direct manufacturer—from base paper production through coating and slitting—Changfa provides end-to-end solutions tailored for global print businesses. Changfa Digital is a professional sublimation paper manufacturer and has been supplying digital printing services for 15+ years. It’s the factory for sublimation papers, from base paper to making coating and slitting and shipping to all of the world.

Their CF-Premium Series is designed for high-speed environments where precision meets productivity. We imported 1 set of the most advanced coating line for sublimation paper production daily from Germany. With monthly exports reaching up to 120 containers globally, the total production value is 3000 Tons per month. Their scale ensures consistent availability even under tight deadlines.

Choosing the Right Paper for Your Workflow

To maximize performance, selecting appropriate paper is critical based on your setup.

Factors to Consider: Ink Compatibility, Drying Time, Transfer Rate

You’ll want papers that match your printer’s head type (e.g., Epson I3200), deliver rapid drying times under ambient humidity conditions, and offer optimal release rates during pressing. Excellent fluency, 360dpi continuously printing 20 meters without breaking, ensures smooth operations without clogging issues.

Matching Paper Type With Printer Model and Heat Press Settings

Paper weights vary from 29gsm up to 100gsm. Our main products: 29gsm,35gsm,40gsm, 50gsm, 60gsm, 70gsm, 90gsm, depending on application needs such as stretchability or surface absorption. Lighter weights suit fast presses; heavier ones support bold saturation levels under prolonged dwell times.

Maximizing Output Quality

Even top-tier equipment can’t compensate for poor handling practices. Keep unused rolls sealed in moisture-proof packaging at room temperature. Avoid extreme humidity swings that may warp coatings or affect ink absorption rates during printing. Use calibrated ICC profiles specific to your substrate type. Pre-press garments briefly before full transfers to remove moisture content—this prevents ghosting effects during final application stages. We have professional staff online service and solve the problems you encounter for you. Welcome to use Changfa Digital’s Products.

Future-Proofing Your Business With Sublimation Technology

As customization becomes mainstream across industries—from fashion to promotional goods—sublimation remains one of the most agile technologies available today.

Consumers expect fast delivery times without compromising quality. Inkjet sublimation enables just-in-time manufacturing models where inventory risks are minimized while customer satisfaction soars through personalization options. By eliminating water usage typical in traditional dyeing methods—and reducing chemical waste—sublimation aligns well with eco-conscious business models. Adopt environmentally friendly solventssafe and nontoxic further supporting sustainable branding narratives you may promote within your marketing channels.

FAQ

Q: What kind of fabrics work best with inkjet sublimation transfer paper?

A: Polyester fabrics or polymer-coated surfaces yield optimal results because they allow dye molecules from sublimation inks to bond effectively during heat pressing.

Q: How do I choose between different GSM levels when buying transfer paper?

A: Lighter GSM (like 29–40gsm) is ideal for high-speed printers where fast drying is needed; heavier GSM (70–100gsm) supports rich saturation levels but may require longer dwell times during pressing cycles.

Q: Can I start a print business using only one printer model?

A: A reliable unit like the Changfa Digital CF-2000 Sublimation Transfer Paper Digital Printer can absolutely kickstart your print business. This beast handles high-volume sublimation printing with ease, spitting out vibrant, durable designs on polyester fabrics or coated hard surfaces.